- Home | Industry Update | Autoneum Develops Advanced Front Trunk Solution For Battery ...

Autoneum Develops Advanced Front Trunk Solution for Battery Electric Vehicles

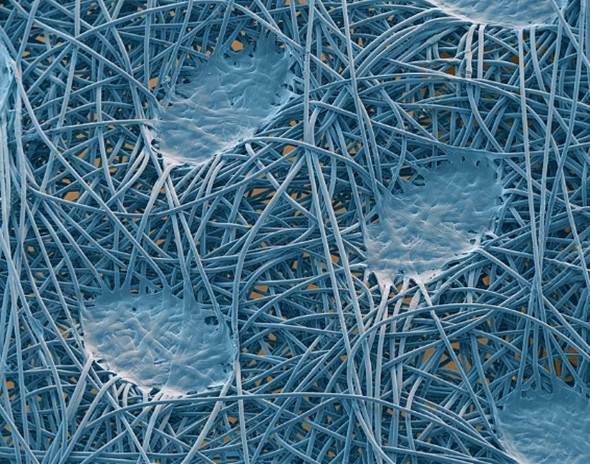

Autoneum, the Swiss automotive supplier renowned for its lightweight and sustainable acoustic and thermal management solutions, has introduced a new front trunk (frunk) system specifically engineered for battery electric vehicles (BEVs). This innovative solution is made entirely from polyester-based Ultra-Silent textile technology, marking a significant shift from conventional plastic-based frunk components.

Innovative Material and Design

The Ultra-Silent Frunk leverages a polyester-based textile construction, which allows for exceptional lightweight performance and functional integration. Unlike traditional frunk systems composed of multiple hard plastic parts, Autoneum’s design is a single, monomaterial component—streamlining manufacturing and reducing complexity.

Key Performance Benefits

-

Weight Reduction: The textile frunk delivers substantial weight savings, helping to enhance overall vehicle efficiency and potentially extend the driving range of electric vehicles.

-

Acoustic and Thermal Insulation: Ultra-Silent’s sound-absorbing properties reduce noise both inside and outside the vehicle. It also improves thermal insulation, as evidenced by tests where ice stayed frozen in the frunk for up to 28 hours at 30 °C ambient temperature—performance that surpasses many conventional plastic alternatives.

-

Sustainability: Up to 70% recycled content is incorporated into the polyester material, supporting manufacturers’ goals to reduce carbon footprints and material waste.

-

Design Flexibility: Autoneum’s solution can be tailored to meet specific aesthetic and technical requirements of different OEMs, enabling scalable integration across multiple vehicle platforms.

Market Adoption and Production

Autoneum’s Ultra-Silent front trunk has already attracted initial orders from three major original equipment manufacturers (OEMs) across Asia and Europe. Series production for two BEV models is reported to be underway in China and Germany since 2025, with production for additional vehicles expected to begin shortly.

Supporting the EV Transition

In the context of electric mobility, the absence of a combustion engine enables use of under-bonnet space for additional storage—termed the “frunk”. Autoneum’s polyester-based frunk not only utilizes this space efficiently but also brings added benefits in vehicle performance and sustainability.

With growing global demand for BEVs, suppliers like Autoneum are expanding their focus on lightweight, sustainable components that help manufacturers meet stricter emissions and efficiency requirements.

06:16 PM, Feb 11

Other Related Topics

.webp)

USâBangladesh Tariff Pact Brings Fresh Momentum to Garment Exports

04:08 PM, Feb 10

Essity Finalizes Acquisition of Edgewellâs Feminine Care Business

06:07 PM, Feb 09Industry Update

Union Budget 2026: Giriraj Singh Hails âViksit Bharat Budgetâ Driving Textile Growth...view more

Kolkata Set to Become Textile Sourcing Hub as YARNEX and TEXINDIA Return in January 2026...view more

.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

_large1.jpeg)

.png)

.jpg)

1.jpeg)