Raw Material In Spandex-Based Fabric Manufacturing: Focus On Polyurethane

Share Post

Polyurethane is a polymer composed of organic units joined by urethane links. Its creation involves the chemical reaction of a diisocyanate with a polyol. What makes polyurethane extraordinary is its ability to be formulated for both rigid and flexible applications, making it one of the most adaptable polymers in industrial use. In textile applications, particularly for spandex manufacturing, polyurethane exists in a soft, elastic form that allows for significant extension and recovery. Its adaptability in fiber formation is a result of its segmented structure consisting of alternating soft and hard segments.

Polyurethane is a versatile polymer formed through a chemical reaction between a diisocyanate and a polyol, creating organic units connected by urethane links. This synthesis enables it to be customized for a wide range of applications, from rigid foams to soft, flexible fibers. In the textile industry, polyurethane is especially valued for its elasticity and durability, making it a key component in spandex fiber production. Its flexibility and resilience are what make it one of the most widely used polymers across various industries.

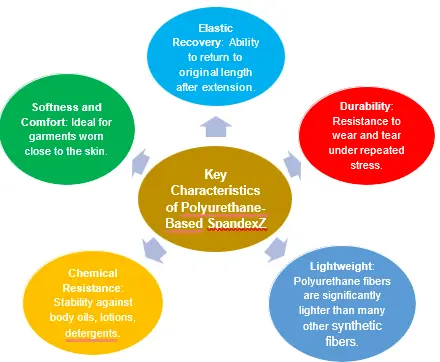

In its fiber form, polyurethane functions as a thermoplastic elastomer, characterized by a segmented structure with alternating hard and soft segments.These segments are typically made from urethane (hard) and polyol (soft), which give the fiber its unique properties such as high elongation, excellent stretch and recovery, and long- lasting performance. The polyether or polyester polyols used in the formulation further influence the texture and behavior of the final product, allowing manufacturers to fine-tune characteristics based on the end-use.

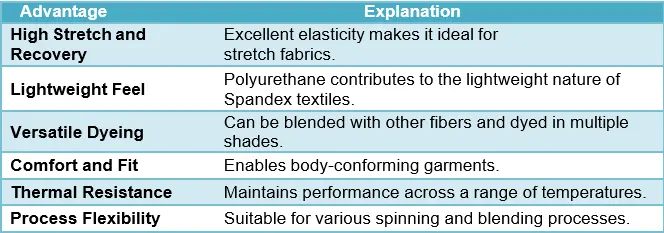

Polyurethane-based fibers are lightweight yet highly durable, making them ideal for applications where flexibility and comfort are essential. In textiles, these fibers are predominantly used in the production of spandex yarns, which are widely utilized in stretchable sportswear, medical textiles, and form-fitting garments. Thanks to its adaptive chemical structure and performance traits, polyurethane continues to be a cornerstone material in creating functional and high- performance textile products.

The production of polyurethane involves several key chemical components that define its structure and properties. Diisocyanates, such as Toluene Diisocyanate (TDI) and Methylene Diphenyl Diisocyanate (MDI), are reactive compounds responsible for forming the hard segments of the polymer chain. The soft segments are contributed by polyols, with polyether polyols offering superior hydrolytic stability and polyester polyols providing enhanced strength. To regulate the polymerization process, chain extenders and catalysts are introduced, which help manage chain length and cross-linking.

Additionally, various additives like surfactants, stabilizers, and colorants are included to improve performance characteristics, dyeability, and surface finish, making polyurethane highly versatile in end-use applications.

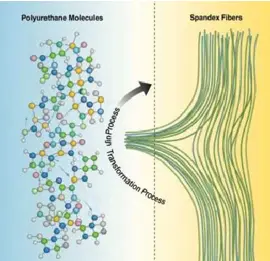

The manufacturing of spandex fiber from polyurethane involves synthesizing the polymer followed by extrusion into fibers. The process generally follows the dry spinning method, which is preferred due to its control and scalability.

Steps in Dry Spinning of Polyurethane- Based Spandex:

-

Polymer Synthesis: The raw polyurethane is synthesized in solution. This involves mixing diisocyanates with polyols and catalysts in a solvent (like DMF – dimethylformamide).

-

Solution Preparation: The polymer solution is homogenized to ensure consistency in fiber properties.

-

Extrusion: The polymer solution is extruded through spinnerets into a spinning cell where warm air evaporates the solvent.

-

Fiber Solidification: As the solvent evaporates, the fibers solidify and retain the required tensile and elastic properties.

-

Drawing and Winding: The fibers are stretched (drawn) to align the polymer chains, which enhances elasticity. The final fibers are wound onto spools.

Polyurethane imparts a range of properties that are highly valued in spandex fibers:

Advantages of Using Polyurethane in Spandex-Based Textiles:

Polyurethane, despite its wide range of applications and adaptability, does come with certain limitations that pose challenges in both manufacturing and end-use scenarios. Polyester-based polyurethanes are particularly sensitive to hydrolysis, making them vulnerable in humid or moist environments. Additionally, exposure to ultraviolet (UV) light can lead to gradual degradation of polyurethane Fibers, reducing their performance and longevity over time. The production process itself is also cost-intensive, as it requires high- purity chemicals and tightly controlled environmental conditions. Moreover, the use of solvents in processes like dry spinning can raise environmental and health concerns if not managed with proper safety and disposal measures.

Even with these challenges, polyurethane- based spandex remains indispensable across various sectors due to its unique combination of elasticity, strength, and comfort. In the apparel industry, it plays a vital role in stretchable garments ranging from everyday casual wear to high- performance sportswear, helping maintain fit and shape. In the medical field, spandex is used in compression garments, wound care products, and prosthetics, where flexibility and skin-conforming properties are crucial. Home textiles also benefit from polyurethane’s stretchability in items like fitted sheets and upholstery, while the intimate apparel sector relies heavily on its ability to provide both support and comfort in products such as lingerie and shapewear.

As the textile industry evolves, polyurethane continues to be at the forefront of innovation, particularly through its role in spandex manufacturing. Its segmented chemical structure allows for fine-tuning of fiber characteristics, giving manufacturers the ability to engineer fabrics that respond to a wide variety of performance needs. Simultaneously, there’s a growing emphasis on sustainability, with ongoing research into bio-based polyols, solvent-free spinning techniques, and waste-reducing practices. These efforts are reshaping the environmental footprint of polyurethane, positioning it as a material that can meet the demands of the future without compromising on performance.

In theoretical and practical terms, polyurethane serves as the very foundation of spandex technology. It is more than just a chemical compound it is a driving force that unites science and utility, creating fabrics that stretch, recover, and adapt to human needs in ways no other Fiber can. Whether it’s in athletic wear or medical applications, polyurethane-infused spandex continues to redefine comfort, durability, and innovation, ensuring its relevance and indispensability in the textile industry for years to come.

12:17 PM, Nov 12

A PHP Error was encountered

Severity: Warning

Message: Trying to access array offset on value of type null

Filename: user/single_post.php

Line Number: 293

Backtrace:

File: /home/textilebusiness/nonwoventextiles.in/application/views/user/single_post.php

Line: 293

Function: _error_handler

File: /home/textilebusiness/nonwoventextiles.in/application/controllers/User.php

Line: 3983

Function: view

File: /home/textilebusiness/nonwoventextiles.in/index.php

Line: 316

Function: require_once

.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

().png)